Technical Tuesday No. 3: Offset Printing

What is offset printing and how does the ink get on the paper?

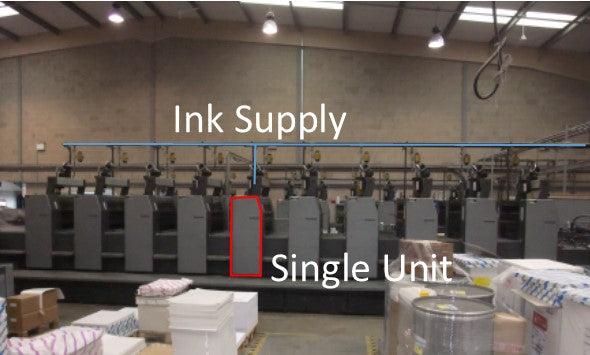

Once the printing plates have been processed (Technical Tuesday No.2), they are attached to the plate cylinders on the printing press. There is one of these in each single unit of the press as shown in the photograph below. Each of our Heidelberg printing presses has 10 units.

8 plates are required for double sided printing and it is essential that they are correctly positioned on the cylinder so that the final print is accurate and 'in register'. Tabs are punched out of one edge of the plates so that they can be inserted and slowly wound into the correct position on the cylinders.

Once the plates have been added onto the cylinders, it’s time to ink up! Ink is fed into reservoirs by overhead pipes to provide a consistent level of ink to the press.

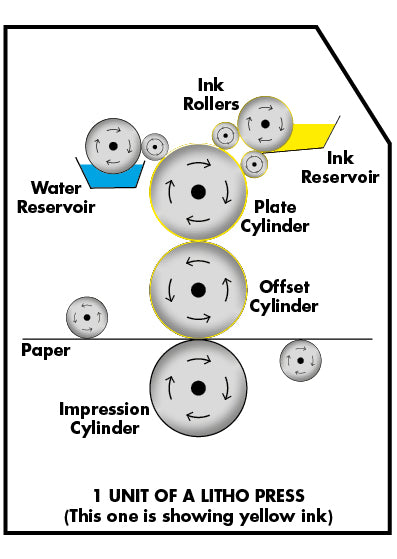

The diagram below shows a (very) basic layout of a single unit on one of our offset litho press.

Ink is stored in the ink reservoir where it is transferred to the printing plate by a series of rollers. Once on the metal printing plate, the image is transferred onto a rubber blanket on the offset cylinder. The ink is pressed onto the paper as it passes between the blanket on the offset cylinder and the impression cylinder. This is where the name 'offset printing (lithography)' comes from, as the metal plate doesn't actually touch the paper.

After the image is transferred onto the offset cylinder from the plate cylinder, the plate cylinder continues it's rotation and is cleaned by the water rollers, before more ink is applied and the process is repeated.

Each units adds a single colour (Cyan, Magenta, Yellow or Black), so a 10 colour press can print both sides of the paper in a single pass (called perfecting) and add a coating to both sides (on the other 2 units) that means the ink is dry by the time the paper reaches the end of the press.