Technical Tuesday No.4: The Deal with Seal

How do you send my leaflets out so quickly? Don't they need time to dry?!

Seal is especially important to our print due to our fast turnaround times...

Our presses are sheet fed presses, meaning our paper is supplied as single sheets in large stacks. There are other similar machines which are web-fed, rather than sheet-fed, which have their paper supplied on large rolls.

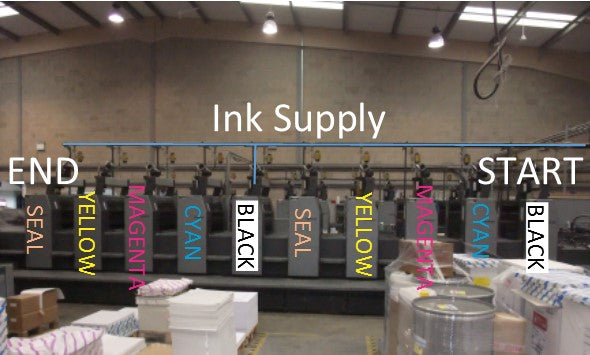

As the paper feeds through each unit of the press, the ink for each of the 4 CMYK colours is applied to form the complete printed side, so the first 4 units apply the ink, whilst the fifth unit applies a seal over the print so that the ink doesn't smudge as it comes off the press. Once the paper has passed through the fifth unit the paper is flipped so that the other sides is printed with 4 colours and then a seal is applied to that side too.

As you can see below, the paper starts from the right, and by the time each sheet has passed through once it has been fully printed both sides, with a seal applied.

The max speed of this Heidelberg SM72 is about 12,000 sheets per hour. Wow!

The sheets exit the press at high speed and form another stack at the end of the press with all the printed sheets lying on top of one another.

Once your proof is approved by 6pm all that day’s normal print jobs (A5’s, A4’s etc.) are plated and are printed overnight. We need to send these (flat) leaflets out to you the next day so they need to be trimmed and boxed straight away. If we didn’t seal the print then we’d be trimming with wet ink, and the force of the guillotine would transfer ink from one side of one sheet to the back of the next all down the stack sticking them all together.

And that is the deal with seal!

Roddy x